BREATHING LIFE INTO THE FUTURE

Did you know that you breathe 12,000 liters of air every day?

Have you ever noticed that most of our activities take place indoors, where we spend about 80% of our life?

Safeguarding and preserving air quality is above all the responsibility of those who design, install and maintain air ventilation systems.

Those who, like ALP, have always been concerned with the heating, ventilation and air conditioning systems know that the internal surfaces of the ductworks play a crucial role in the prevention of human health,in fact – if not adequately designed, built and maintained – they constitute the ideal ground for the proliferation of fungi, molds and bacteria which considerably increase the risk of diseases, discomforts and contagions of a biological nature.

It is precisely for this reason that in 2004 ALP chose to invest, design and develop the ALPactive® Antimicrobial product line:

the natural solution able to sanitise the air we breathe and eradicate it from pathogens dangerous to human health,safeguarding air quality and the consequent life quality.

an unprecedented technological upgrade to the traditional concept of ductwork for air distribution.

THAT MAKES THE DIFFERENCE:

ALPactive® Antimicrobial

ALPactive® technology is a natural active ingredient based on silver ions and zeolite, which is present on every square centimetre of all the ALPactive® ductwork.

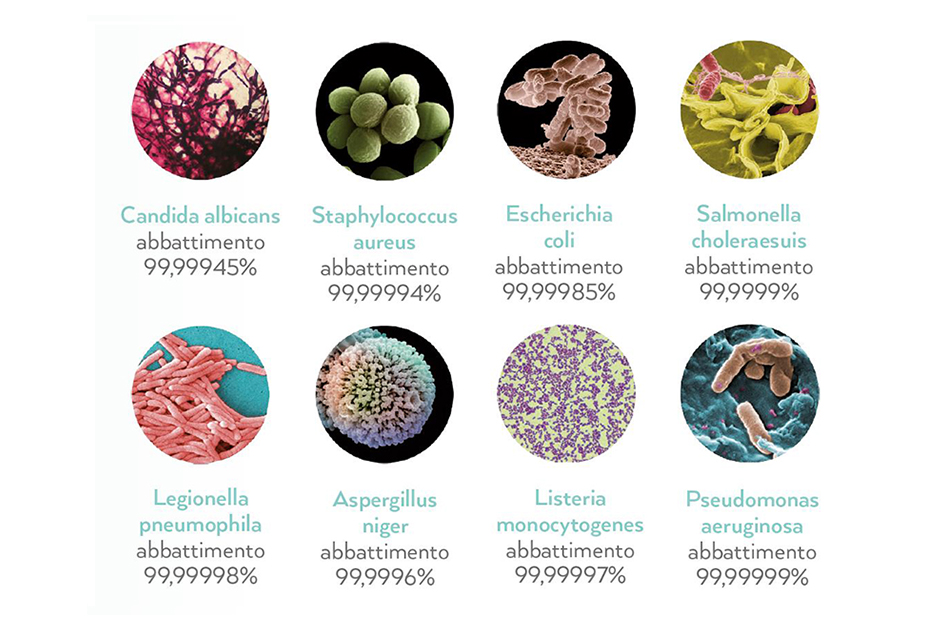

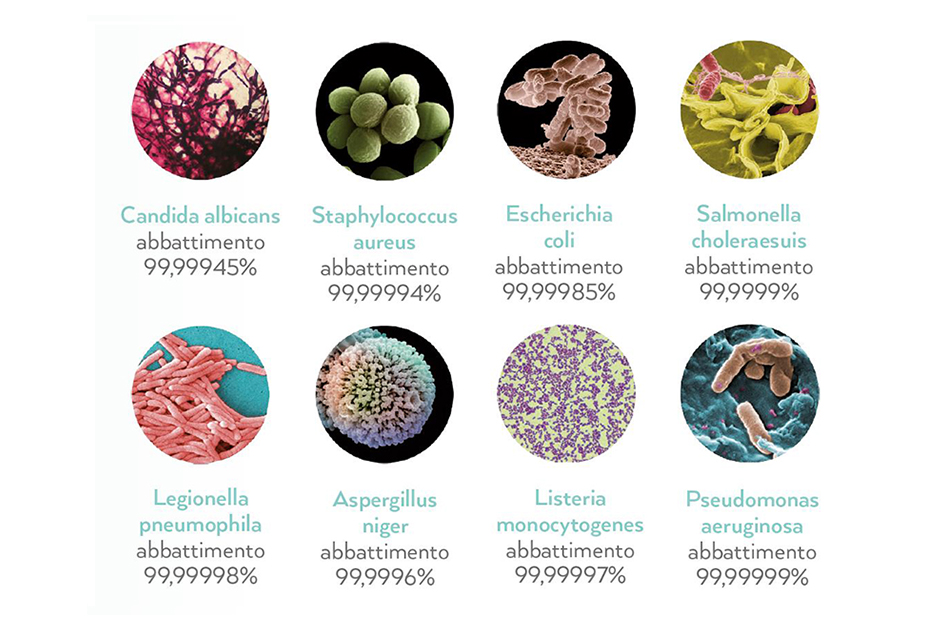

The active ingredient performs a trimodal action, that is able to kill more than 600 familiesof micro-organisms, bacteria, moulds and viral strains,including SARS, CORONAVIRUS, H5N1,with an efficacy of 99.99999%, sanitising the air and preventing the risk of contagion for a minimum guaranteed duration of 15 years.

THE ADVANTAGES

SAFE AND CERTIFIED

In 2006, after 2 years of testing on pilot ventilation systems, the Italian Ministry of Health certified the antimicrobial and self-sanitizing action of the ALPactive® ductworks. Since 2006, ALPactive® technology has been chosen by numerous public and private companies, both national and international. The active ingredient based on silver ions and zeolite has been approved and declared harmless to human health by the most important international control bodies (EFSA, FDA, NSF). ALPactive® technology is VDI 6022 certified since 2016 which ensures that the ductwork and all its components fulfil the market’s strictest hygiene requirements.

AIR QUALITY

The triple antimicrobial,

self-sanitizing and self-cleaning action of the ALPactive® ductworks guarantees the elimination of bacteria, moulds and viruses transported inside the ducts.

These actions prevent the risk of building contamination, ensuring air quality and life quality for the people who live there every day.

ECONOMIC

ALPactive® technology allows for up to 90% savings on ductwork maintenance, cleaning and sanitizing, drastically reducing the economic and social costs resulting from the spread of microorganisms harmful to humans.

INTERNATIONAL STANDARDS

ALPactive® ductworks contribute a building earn points towards the LEED, WELL, BREEAM, GREEN BUILDING CONCIL standards, thanks to the advantages in terms of Indoor Air Quality and Performance.

MORE EFFICIENT AND PERFORMING

ECO-FRIENDLY

All ALPactive® ductwork components

are 100% recyclable and zero impact materials. Aluminium is totally recyclable, glues and silicones are water-based without VOCs, the insulation is free from CFCs, HCFCs and the useful life of these materials is extended through their reuse in the construction industry.

SAFE AND CERTIFIED

In 2006, after 2 years of testing on pilot ventilation systems, the Italian Ministry of Health certified the antimicrobial and self-sanitizing action of the ALPactive® ductworks. Since 2006, ALPactive® technology has been chosen by numerous public and private companies, both national and international. The active ingredient based on silver ions and zeolite has been approved and declared harmless to human health by the most important international control bodies (EFSA, FDA, NSF). ALPactive® technology is VDI 6022 certified since 2016 which ensures that the ductwork and all its components fulfil the market’s strictest hygiene requirements.

AIR QUALITY

The triple antimicrobial,

self-sanitizing and self-cleaning action of the ALPactive® ductworks guarantees the elimination of bacteria, moulds and viruses transported inside the ducts.

These actions prevent the risk of building contamination, ensuring air quality and life quality for the people who live there every day.

ECONOMIC

ALPactive® technology allows for up to 90% savings on ductwork maintenance, cleaning and sanitizing, drastically reducing the economic and social costs resulting from the spread of microorganisms harmful to humans.

INTERNATIONAL STANDARDS

ALPactive® ductworks contribute a building earn points towards the LEED, WELL, BREEAM, GREEN BUILDING CONCIL standards, thanks to the advantages in terms of Indoor Air Quality and Performance.

MORE EFFICIENT AND PERFORMING

The characteristics that distinguish the ALPactive® ductworks make the latter the best solution on the market:

━ Ductwork insulationis 2 times more efficent than normal insulation;

━ The junction systems guarantee air-tightness class C;

━10 times lighterthan a traditional duct;

━ Anti-seismic;

━ Very high mechanical rigidity;

━ Up to 2,000 Pa of pressure in continuous operation.

ECO-FRIENDLY

All ALPactive® ductwork components

are 100% recyclable and zero impact materials. Aluminium is totally recyclable, glues and silicones are water-based without VOCs, the insulation is free from CFCs, HCFCs and the useful life of these materials is extended through their reuse in the construction industry.

THE FEATURES

99,99999%

ANTIMICROBIAL

ALPactive® antimicrobial action is able to kill 99.99999% of the pathogens that are deposited inside ductworks, preventing the risk of contagion. Ask for more information

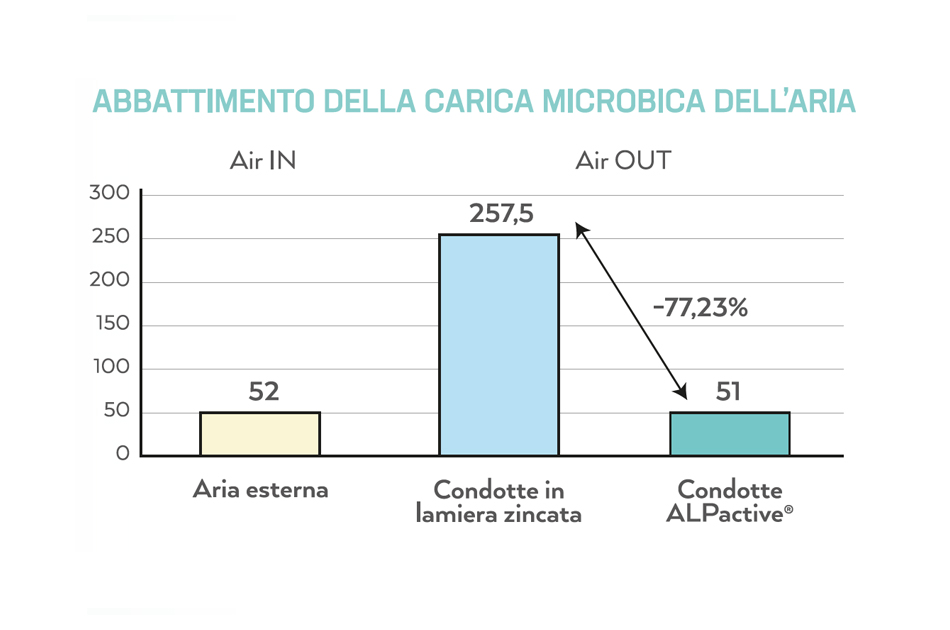

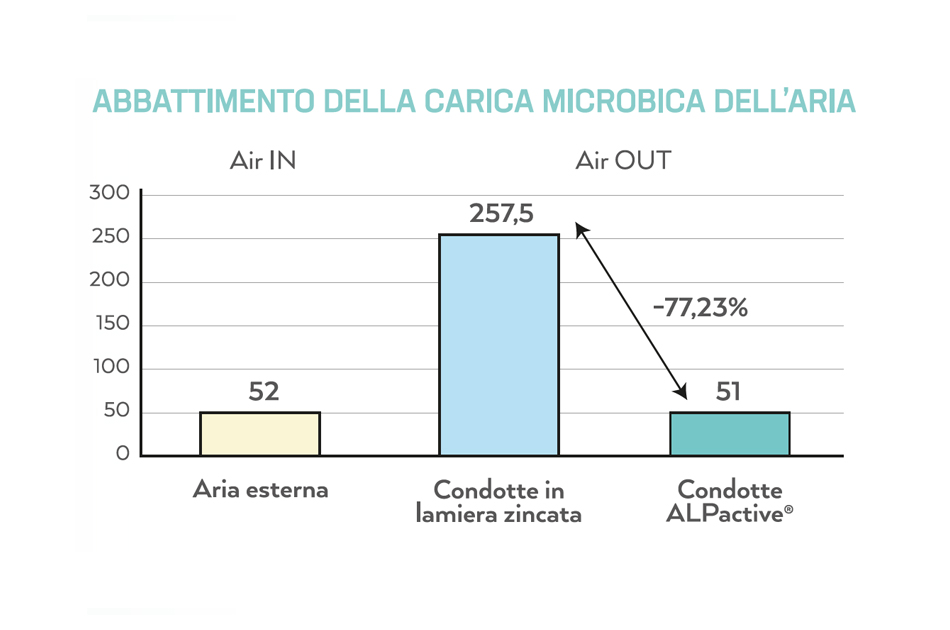

77,23%

SELF-SANITIZING

Air flowing out ALPactive® ductwork has a 77.23% lower airborne microbial load than the air coming from a traditional metal ductwork. (test carried out by the Italian Ministry of Health in 2004).

100%

NATURAL

ALPactive® technology is based on a natural active ingredient composed of silver ions and zeolite, which are 100% natural and non-dangerous for humans. Ask for more information

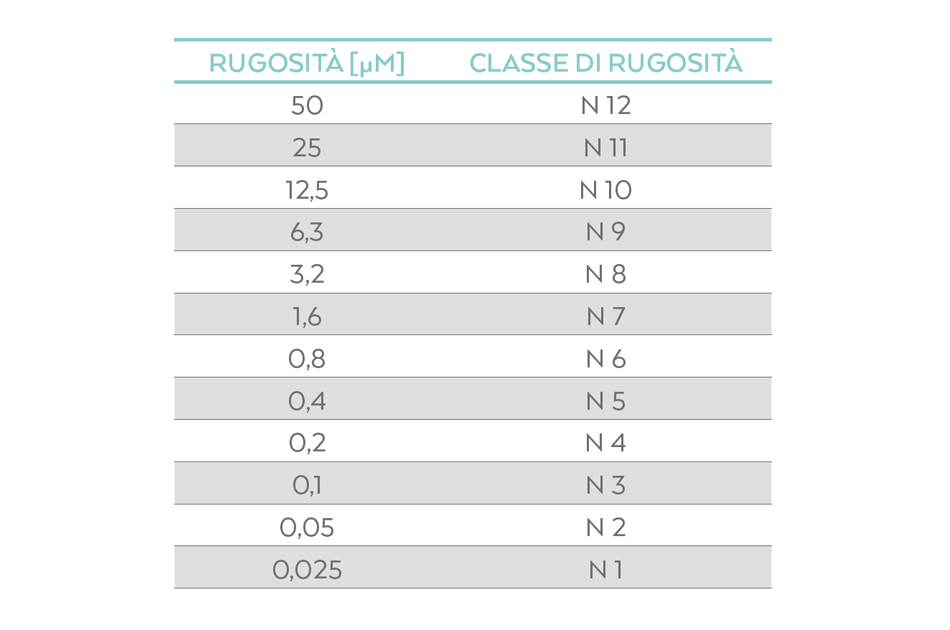

50%

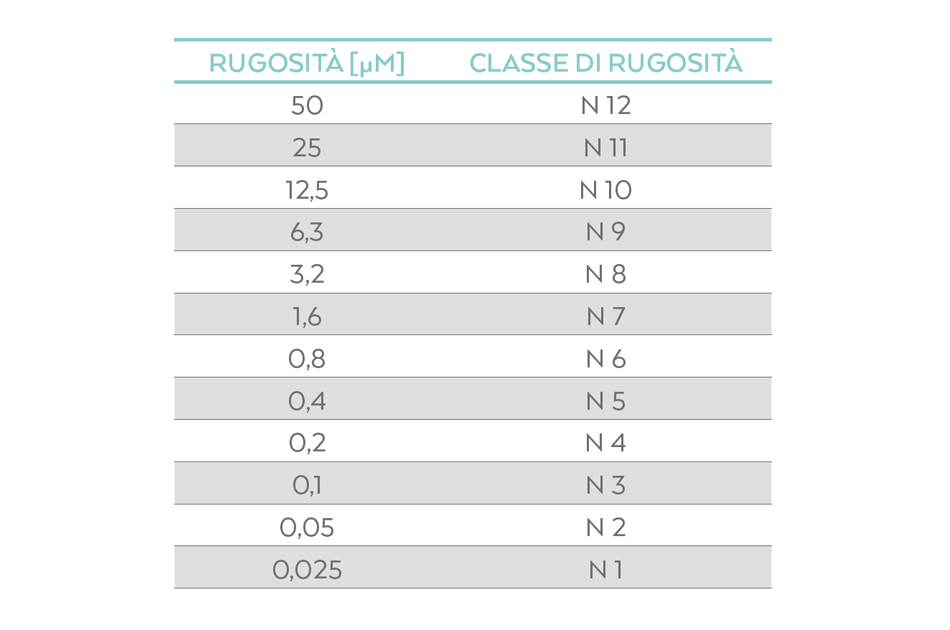

SELF-CLEANING

The patented surface of the ALPactive® ductwork features a smooth finish such as to achieve the N2 class of equivalent roughness, reducing the deposit of dust by 50% compared to galvanized sheet metal ductwork.Ask for more information

600 + VDI 6022

LABORATORY TESTS

The antimicrobial efficacy is active and tested on over 600 families of microbes, bacteria, fungi and viral strains. ALPactive® products are VDI 6022 certified, which ensures that the ductwork and all its components fulfil the market’s strictest hygiene requirements. Ask for more information

600 + VDI 6022

PATENTED

The patented ALPactive® panels exploit the physical features of the materials that constitute them, including the active ingredient based on silver ions and ziolite, the bacteriostaticity of aluminum and the excellent degree of insulation of the polyurethane. The extraordinary technical features and the proved effects they have on the working operations and on the air quality are the guarantee also for the construction of ductworks with large dimensions.Ask for more information

15 YEARS

WARRANTY

The self-sanitizing and self-cleaning antimicrobial action and efficiency has a guaranteed minimum duration of 15 years, equal to the case history of ALPactive® applications monitored by us.Ask for more information

THE FEATURES

ANTIMICROBIAL

ALPactive® antimicrobial action is able to kill 99.99999% of the pathogens that are deposited inside ductworks, preventing the risk of contagion.

SELF-SANITIZING

Air flowing out ALPactive® ductwork has a 77.23% lower airborne microbial load than the air coming from a traditional metal ductwork. (test carried out by the Italian Ministry of Health in 2004).

NATURAL

ALPactive® technology is based on a natural active ingredient composed of silver ions and zeolite, which are 100% natural and non-dangerous for humans. The extraordinary technical features and the proved effects they have on the working operations and on the air quality are the guarantee also for the construction of ductworks with large dimensions.

SELF-CLEANING

The patented surface of the ALPactive® ductwork features a smooth finish such as to achieve the N2 class of equivalent roughness, reducing the deposit of dust by 50% compared to galvanized sheet metal ductwork.

LABORATORY TESTS

The antimicrobial efficacy is active and tested on over 600 families of microbes, bacteria, fungi and viral strains. ALPactive® products are VDI 6022 certified, which ensures that the ductwork and all its components fulfil the market's strictest hygiene requirements.

ALP INTERNATIONAL

The patented ALPactive® panels exploit the physical features of the materials that constitute them, including the active ingredient based on silver ions and ziolite, the bacteriostaticity of aluminum and the excellent degree of insulation of the polyurethane. The extraordinary technical features and the proved effects they have on the working operations and on the air quality are the guarantee also for the construction of ductworks with large dimensions.

WARRANTY

The self-sanitizing and self-cleaning antimicrobial action and efficiency has a guaranteed minimum duration of 15 years, equal to the case history of ALPactive® applications monitored by us.

WE RESPOND

TO YOUR NEEDS

Designing, building and maintaining an air ventilation system has never been so simple, economical and sustainable.

ALPactive® Antimicrobial systems guarantee numerous advantages to all interested stakeholders, and their performance makes them the solution to problems both in the design phase and in the installation and maintenance phase of the ventilation system.

CONSULTANT

even to the most complex design requirements:

■Compliant with fire prevention

and seismic risk prevention;

■Suitable for any design situation;

■Best energy performance available on the market;

■It contributes to earning points towards LEED,

BREAM, WELL, GREEN BUILDING;

■Savings on installation structures, reduction of load

on supporting structures.

AND MAINTAINER

even to the most complex design requirements:

■Compliant with fire prevention

and seismic risk prevention;

■Suitable for any design situation;

■Best energy performance available on the market;

■It contributes to earning points towards LEED,

BREAM, WELL, GREEN BUILDING;

■Savings on installation structures, reduction of load

on supporting structures.

ALPactive® system effectively and efficiently responds even to the most complex design requirements:

ALPactive® system effectively and efficiently responds even to the most complex design requirements:

■Compliant with the prevention and safety regulations in the workplace;

■Suitable for any design situation;

■Best energy performance available on the market;

■It contributes to earning points towards LEED, BREAM, WELL, GREEN BUILDING;

■Savings on installation structures, reduction of load on supporting structures.

GET IN TOUCH WITH US FOR MORE INFO

Our team is available for information, offers and insights about ALPactive®.

ALPactive® ductwork brings immediate and long-lasting benefits to decision-makers:

ALPactive® ductwork brings immediate and long-lasting benefits to decision-makers: ALPactive® system means savings and versatility to duct engineers keen everyday on conscious choices:

ALPactive® system means savings and versatility to duct engineers keen everyday on conscious choices:

ALPactive® ductwork is functional and guarantees easy installation and mainteinance management:

ALPactive® ductwork is functional and guarantees easy installation and mainteinance management: